August is behind us and September is well underway. That means summer is at end and fall nearly upon us. I think April was just “12 minutes ago” and we were all trying to remember what the current year is. Time and space no longer have meaning. With that being the case, it’s important to note that, as of this writing, it is 2022 (not 2020 also).

Time is flying, but the work keeps coming. Just because it seems like we have less time doesn’t mean that we actually do. You still have to drop the same number of parts into your schematic and get the same number of prototypes fabricated, assembled and running. And that is why we are here to help. Here are five reasons to let us do the difficult work this fall.

0: Instead of counting and recounting all of the tiny surface mount parts you need soldered on the board, you can count and recount the number of summer barbeques you no longer need to go out and buy hot dog buns and plastic cups for.

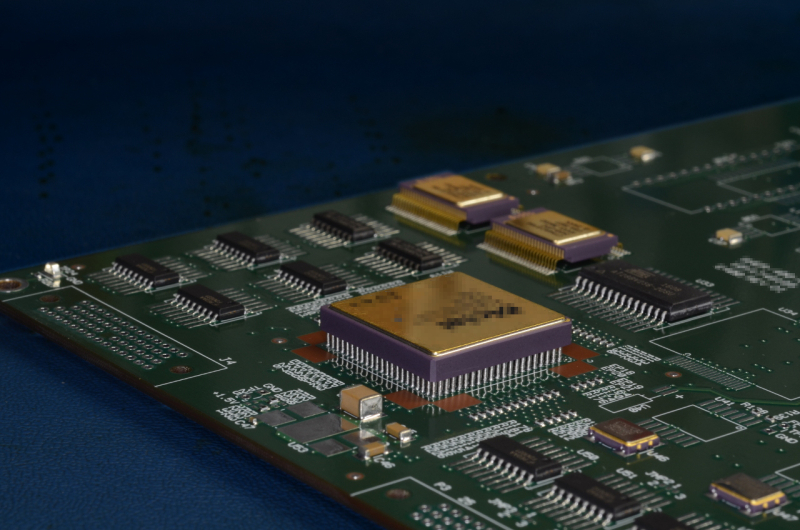

1: If you’re a schematic designer and not a PCB layout specialist, the thought of routing a pair of 0.4 mm pitch BGA MCUs (microcontrollers) along with several high speed differential signals can just throw a pall over your impending Trick-Or-Treat outings. Our San Diego PCB Design group routes complex BGAs like most people eat chocolate bars and candy corn.

With them doing the layout and us building the protos, you are free expend all of your brain cycles on a more creative costume. You’re an engineer – put some blinky lights and motors on it.

2: Instead of soldering, leverage time in extended video meetings into TV time. With your prototypes being safely assembled by us, you can volunteer to sit on various corporate committees. No one will know that you’re watching “Dr. Who” reruns (original or new series are both acceptable) on a side monitor. Just be careful if you’re asked to screen share that schedule spreadsheet you’re pretending to work on.

3: Drop your stress level. If your prototypes are working and you’re tasked with getting a few thousand productions board built, but don’t have six months to a year to spin up a contract manufacturer, talk to Screaming Circuits about Short-Run or Choice-Production service. It takes the burden off you and lets you get your production builds out the door without any long term commitments required.

4: Speaking of long-term commitments, if you do need a traditional electronics manufacturing service (EMS) provider that will be around long enough to support your long-term needs, our parent company, Milwaukee Electronics has been building products since 1954.

5: Five? I’ve already written five reasons. I started at zero like my background in software says I should.

Even with the world seemingly in chaos, the core of what we all do stays – and that is the real reason we are here to help. Just take a quick hop to the Screaming Circuits PCBA quote page and see how we can help get that project built while there’s still a bit of the season left.

Duane Benson

It’s not just software that starts counting at zero. FPGAs do too.